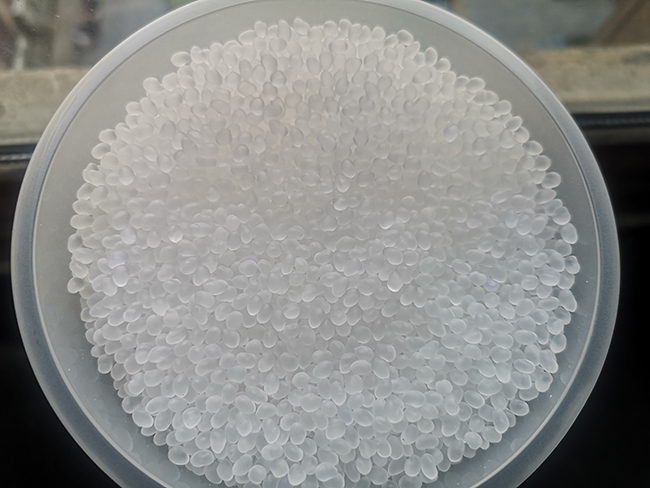

Thermoplastic Elastomers (TPEs)

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers, are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties. While most elastomers are thermosets, thermoplastics are in contrast relatively easy to use in manufacturing, for example, by injection molding. Thermoplastic elastomers show advantages typical of both rubbery materials and plastic materials.

There are six generic classes of commercial TPEs

Styrenic block copolymers, TPS (TPE-s)

Thermoplastic polyolefinelastomers, TPO (TPE-o)

Thermoplastic Vulcanizates, TPV (TPE-v or TPV)

Thermoplastic polyurethanes, TPU (TPU)

Thermoplastic copolyester, TPC (TPE-E)

Thermoplastic polyamides, TPA (TPE-A)

Not classified thermoplastic elastomers, TPZ

In short, TPEs are a family of rubber like materials that combine the characteristics of rubber with the recyclability and processing advantages of plastics. TPEs includes TPE, TPR, TPV, TPU etc.

In China, TPE refers to compounds based on SEBS(Styrene-Ethylene-Butadiene-Styrene), TPR refers to compound based on SBS(styrene-butadiene-styrene). In fact, the words SBS or SEBS are often used to describe these compounds when they are in fact raw materials. By describing compounds as SBS or SEBS it enables us to know the general level of performance and properties of the compound.

SBS is based on two-phase block copolymers with hard and soft segments. The styrene end blocks provide thethermoplastic properties and the Butadiene mid-blocks provide the elastomeric properties. SBS is probably the highest volume material produced and is commonly used in footwear, adhesives and lower specification seals and grips, where resistance to chemicals and aging are not critical.

SBS, when hydrogenated, becomes SEBS, as the elimination of the C=C bonds in the butadiene component generated ethylene and butylenes mid-block, hence the SEBS acronym. SEBS is characterised by improved heat resistance, weather resistance, mechanical properties and chemical resistance.

Hongshuo compounds based on SEBS exhibit excellent weathering, UV and ozone resistance making them ideal choice for outdoor and long service life applications.

Rubber is an organic polymer that needs to be vulcanized to maintain high elasticity within the temperature range (-50 to 150 ).

Thermoplastic elastomer TPE, an environmentally friendly non-toxic polymer material. TPE material combines the high elasticity of rubber with the processing properties of plastics, does not require vulcanization, and easy processing. It is the preferred raw material by more and more customers to replace PVC, rubber and silicon.

Thermoplastic olefinic elastomers (TPOs) consist of PP, PE or other polyolefin as hard segments and rubber component such as ethylene propylene rubber (EPM, EPDM) as soft segments.

TPO is often used in outdoor products such as roofing for all-terrain vehicles, automobiles, golf carts, and other vehicles.

TPV is a blend of dynamically vulcanized elastomer of PP and EPDM. TPV can actually be regarded as a type of TPO, but because of its special dynamic vulcanization system, it gives its excellent comprehensive performance.

TPV, thermoplastic Vulcanizate, part of the TPE family of polymersbut are closest in elastomeric properties to EPDM thermoset rubber, combining the characteristics of vulcanized rubber with the processing properties of thermoplastics.

Suzhou Hongshuo TPV has excellent weather resistance and ozone resistance and were mainly used in automotive parts, seals, construction and electronic communications.

Features of Suzhou Hongshuo TPV:

1.Good elasticity and compression deformation resistance, environmental and aging resistance as EPDM, oil and solvent resistance as CR

2.Wide range of temperature for application (– 60—150℃), wide range of hardness (Shore 45A - Shore 54D), easy dyeing, greatly improve the freedom of product design

3.Excellent processing performance: suitable for injection, extrusion, blow molding and other thermoplastic processing methods, efficient, simple, no need to add equipment, adjustable liquidity, low shrinkage

4.Green environmental protection, recyclable use, repeated use of six times no significant decline in performance, in line with EU environmental requirements

5. Light weigh (0.90 - 0.97), sub-gloss and homogeneous appearance, high surface quality, smooth and soft to touch

A wide variety of customized TPE TPV options are available to you, such as:

1. Different strength, hardness, colors, elasticity, flame retardant, sub-gloss, shine, transparency, wear resistance,

2. Different processes, e.g, injection molding, extrusion, blow molding, lamination.

3. Prefer to adhesion to PP, PE, ABS, PC, PA, POM and other materials by injection molding, secondary injection molding or double color injection molding.

More details, please feel free to contact us.

Q1: What is the common quantity of TPE material per square meter for bath mats?

A: Normally 600-1000 grams per square meter

Q2: Our products are with piles 14-35 mm. Is it possible to be coated with TPE?

A: Sure. The length of the pile does not affect TPE back coating.

Q3: Is TPE for coating clear transparent or it is white?

A: White

Q4: The fabric yarn of our carpet is polyester, do we need to precoat EVA, and then coat TPE material?

A: It depends on your customer needs. If need to fix the yarn, it is better precoat EVA. If not, you can coat TPE material directly.

Normally, TPE glue has good performance with PP fabric yarn.

For polyester, PA etc, we will help to adjust formulation to ensure good coating.

Q5: We want to get oil off a carpet

A: We have developed a new type of TPE material to solve this problem.

Hard engineering plastics e.g. PP have many advantages when used in many products, but they are easy to break at low temperatures.

We have specially developed the toughening TPE material to solve the problem.

This type of TPE material is widely used in plastic mosaic floors, Plastic trays, and milk teacups.

Features of this type of TPE material are as follows:

- Better compatibility and can improve PP toughness and flexibility;

- TPE Percentage : 10%-30%

- Low-temperature resistance

- Not easy to break

Thermoplastic elastomer TPE material has passed RoHS, REACH, Prop 65 certification and meets environmental protection requirements. It is an ideal toys material. It can be used in pet toys, children's and adult toys such as flying discs, luminous balls, etc.

The material expansion rate is 1%-1.5%. The color of Thermoplastic elastomer TPE is natural, transparent, and translucent. The hardness can be 0-90 Shore A.